What is 3D Scanning? Technology Applications and Advantages;

With the rapid advancement of technology, 3D scanning has become a significant innovation in many industries. From engineering to art, from healthcare to automotive, this technology is one of the fastest and most precise ways to transfer physical objects into the digital world.

So, what is 3D scanning, and how does it work? In which industries is this technology used, and what advantages does it offer? Let’s explore the details together.

What is 3D Scanning?

3D scanning is the process of analyzing the dimensions, shape, and surface texture of a physical object with high precision to create a digital model. 3D scanning devices collect millions of data points from the object's surface and process them in a computer to generate a detailed three-dimensional model.

This technology accelerates design and production processes while also allowing the digitization of existing objects for archiving purposes. It has brought a major revolution, especially in the fields of engineering, healthcare, and art.

3D Scanning Technologies and How They Work

3D scanners use different methods to scan the surface of objects and create digital copies. The main 3D scanning technologies include:

Laser-Based 3D Scanning

- Uses laser beams to scan an object.

- The device directs a laser at the object and measures the distance using the reflected light.

- Commonly used in industrial and engineering applications where precision is required.

Structured Light Scanning

- Projects a specific pattern of light onto an object.

- The deformation of the light is analyzed to determine the object's surface structure.

- Preferred for high-precision scans.

Photogrammetry

- Uses multiple photos taken from different angles and processes them through software to create a 3D model.

- Mostly used in archaeology, art, and game development.

Each method has its own advantages and is selected based on the object’s structure and project requirements.

How Does the 3D Scanning Process Work?

The 3D scanning process typically involves the following steps:

- Preparation: The object to be scanned is placed in a suitable position, and if necessary, surface cleaning is performed.

- Scanning: The chosen 3D scanner captures all surface details and collects data.

- Data Processing: The collected point cloud is processed using specialized software to create a complete 3D model.

- Usage: The final digital model is used for manufacturing, analysis, or design purposes.

This process simplifies design and production while also making it possible to reproduce physical objects using 3D printers.

Reverse Engineering and 3D Scanning

Reverse engineering is a method used to analyze and redesign an existing product or component. 3D scanning technology plays a crucial role in this process. It is widely used for reproducing damaged parts, analyzing manufacturing defects, and accelerating product development.

Applications of Reverse Engineering:

- Automotive: Used for spare part production and design improvements.

- Aerospace & Defense: Helps reproduce old or damaged aircraft components digitally.

- Medical: Enables the creation of custom prosthetics and implants.

- Art & Archaeology: Used for digitizing and restoring historical artifacts.

Thanks to this process, physical objects can be copied and enhanced without needing to be designed from scratch.

How is 3D Scanning Integrated with 3D Printing Technology?

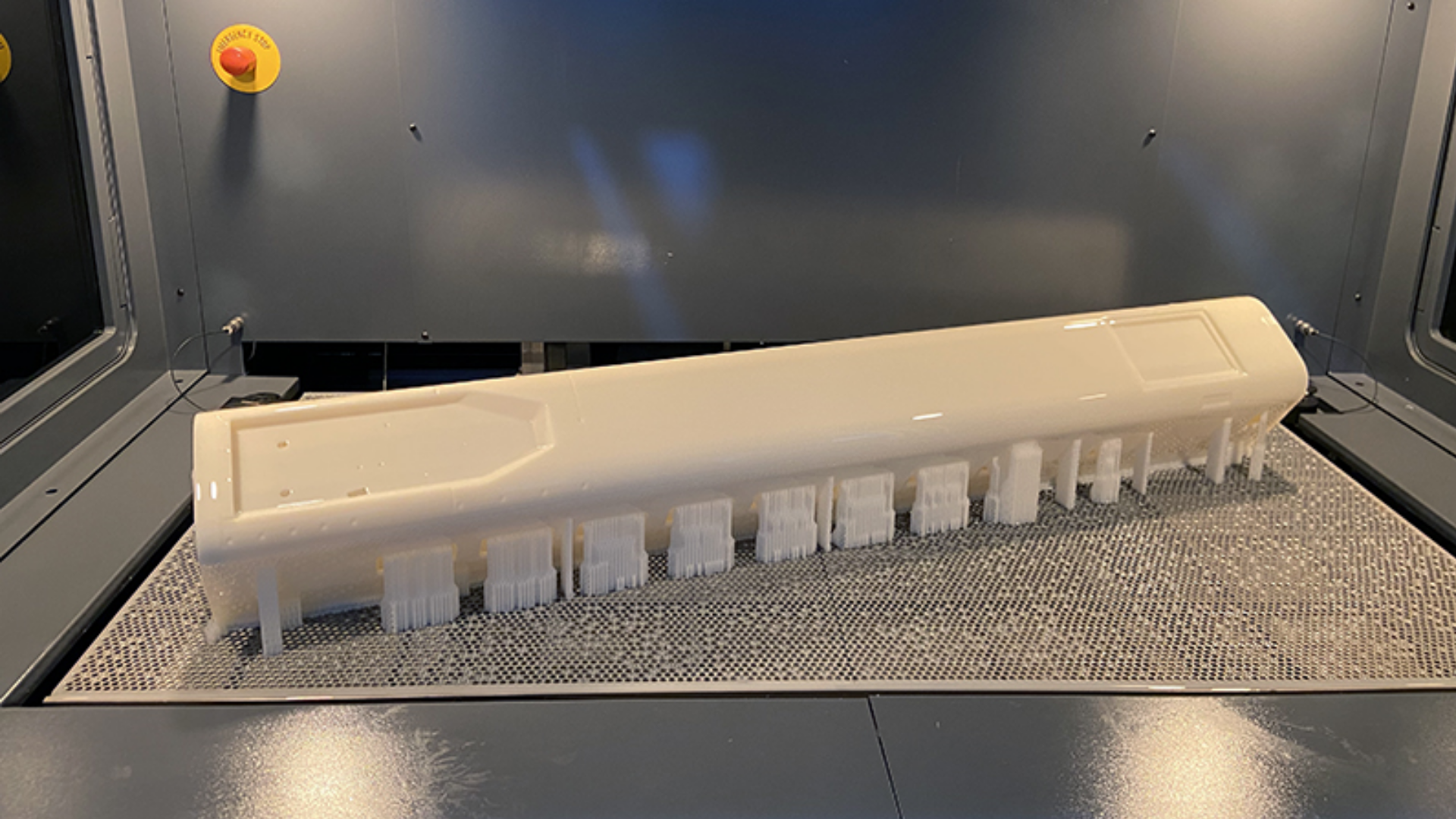

3D scanning and 3D printing work seamlessly together, allowing scanned objects to be reproduced directly via 3D printers. This integration is particularly beneficial in rapid prototyping and product development.

For example:

- An object is scanned to obtain a digital model.

- The model is edited on a computer for optimization and improvements.

- The optimized model is then printed via a 3D printer for physical use.

This reduces production costs while also accelerating the design process.

Advantages of 3D Scanning

3D scanners and services provide numerous benefits for businesses and individuals:

✔ Fast & Accurate Solutions: Physical objects can be digitized in minutes.

✔ Cost Savings: Reduces production errors and lowers overall costs.

✔ Design Flexibility: Even complex geometries can be easily modeled.

✔ Archiving & Preservation: Important objects can be digitally stored for long-term protection.

By utilizing 3D scanning services, businesses can improve production efficiency and accelerate design and analysis workflows.

Professional 3D Scanning Services with Prodigma

For those looking for high-precision 3D scanning services in Turkey, Prodigma is one of the best options. With state-of-the-art 3D scanners and an expert team, Prodigma provides highly accurate scanning solutions.

Prodigma’s 3D scanning services include:

✅ Industrial scanning services

✅ Reverse engineering support

✅ High-precision measurement and quality control

✅ 3D modeling and CAD design assistance

Shape the Future with 3D Scanning!

3D scanning technology is revolutionizing industries from manufacturing to art. With faster, more precise, and cost-effective production processes, 3D scanning services provide significant advantages.

If you're looking for innovative solutions for your business, get professional support with Prodigma today! 🚀