The Impact of Large Build Volume in SLA Technology on Manufacturing Processes;

In recent years, 3D printing technologies have brought significant transformation to industrial production processes. At the center of this transformation lies SLA (Stereolithography) technology, which, with its large build volume systems, has become a solution that enhances production efficiency. This article examines the effects, advantages, application areas, and opportunities offered by SLA 3D printer systems on manufacturing processes through a scientific, experience-based, and data-driven perspective.

What is SLA Technology and How Does It Work?

Developed in the 1980s, SLA remains one of the most precise and high-quality additive manufacturing methods today. It works by curing photopolymer resins layer by layer using ultraviolet (UV) laser light. Each layer is solidified with micron-level precision, ensuring exceptional surface detail and accuracy.

This technology offers major advantages in detailed prototyping and industrial part production. Processes that traditionally take weeks can be completed within hours with SLA-based prototyping.

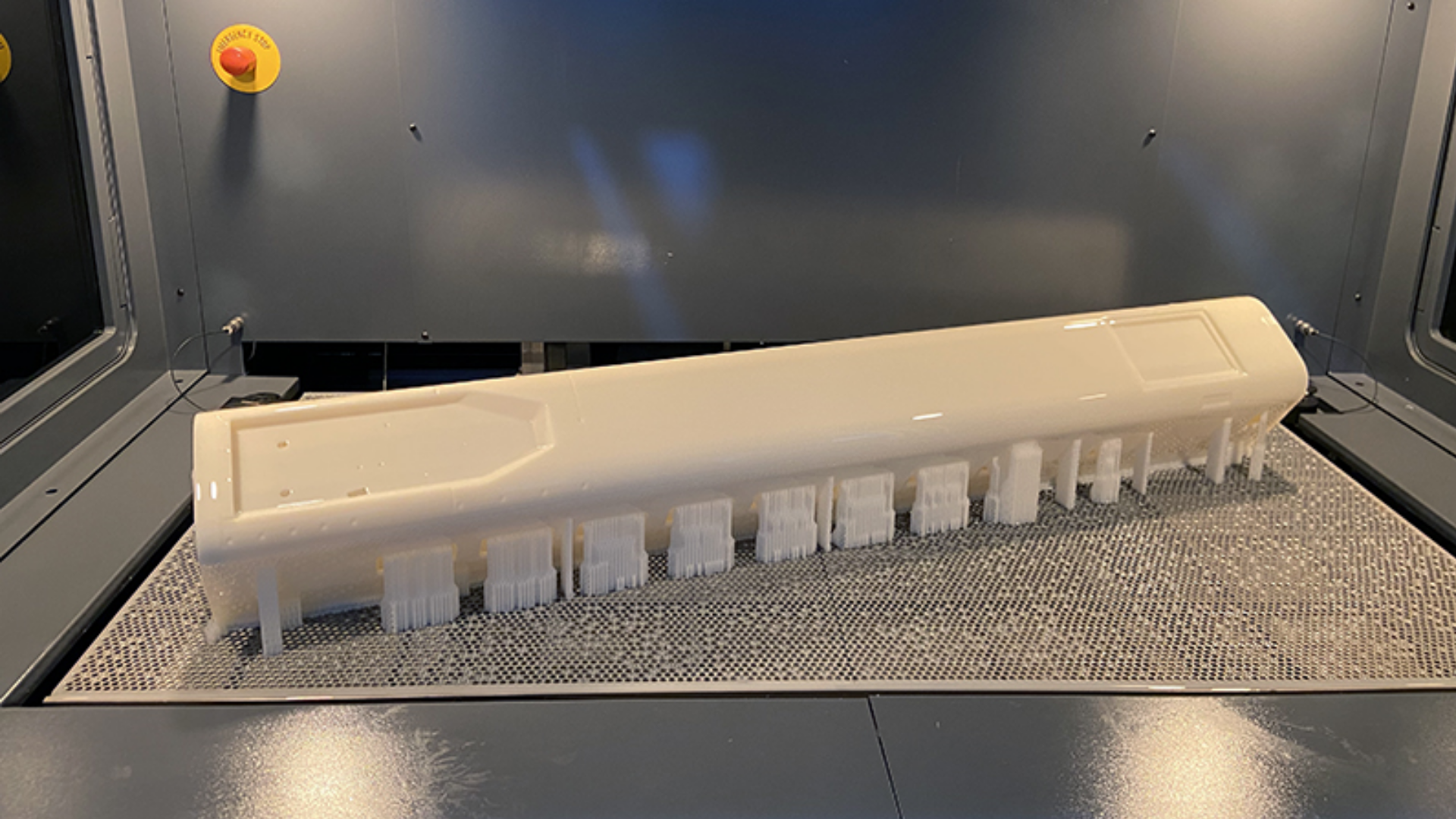

The Effect of Large Build Volume on Manufacturing Processes

A large build volume is a critical factor that directly affects production scale in SLA 3D printing systems. In industrial production, larger build volumes provide several benefits:

- Multi-Part Production: Enables simultaneous printing of multiple parts, reducing overall production time.

- Single-Piece Manufacturing: Large objects can be printed in one piece without assembly.

- Time and Cost Savings: Reduced assembly requirements lower labor costs.

- Consistent Quality: As all parts are produced in a single print cycle, quality variations are minimized.

These advantages make large-format SLA systems indispensable. Prodigma’s high-volume industrial 3D printing services, for instance, help companies gain greater flexibility and speed in transitioning from design to production.

Prototyping with SLA: The Balance of Speed and Precision

In product development, SLA prototyping offers remarkable advantages in both speed and accuracy. SLA systems can achieve layer thicknesses as fine as 0.025 mm, making them ideal for engineering validation prototypes and medical device manufacturing.

The typical SLA prototyping process includes:

- Design preparation: The CAD file is created and transferred to slicing software.

- Printing: The UV laser cures each layer on the resin surface.

- Washing and curing: Printed parts are cleaned with isopropyl alcohol and then UV-cured for final hardening.

- Quality control: Dimensional accuracy and surface finish are inspected.

A large build volume allows multiple prototypes to be produced simultaneously, which is particularly advantageous in automotive, medical, and mold-making industries, offering significant competitive benefits.

Applications of SLA Technology: From Industry to Healthcare

Today, SLA technology is used not only in engineering but also in medical, dental, jewelry, industrial tooling, and aerospace industries. Key application areas include:

- Medical sector: Anatomical models, dental molds, and surgical planning tools.

- Automotive: Rapid prototyping, mold fabrication, and functional test parts.

- Jewelry: Highly detailed casting molds.

- Consumer products: Ergonomic testing and design validation prototypes.

This diversity highlights the adaptability of SLA technology its ability to meet the unique needs of various industries is one of the main reasons for its sustained success.

Advantages of SLA Technology: Why It Should Be Preferred

Large-format SLA 3D printers offer several advantages for manufacturers:

- High resolution and surface quality: Smooth finishes minimize post-processing needs.

- Technological efficiency: Minimal material waste supports environmental sustainability.

- Faster design cycles: The time from design to product is drastically reduced.

- Cost efficiency: Low error rates and fewer revisions reduce overall costs.

- Scalable production: Large volumes enable small and medium-sized manufacturers to perform short-run or serial production.

For example, Prodigma’s industrial SLA solutions accelerate R&D workflows, shortening time-to-market for manufacturers.

The Strategic Importance of Large Build Volume

A large build volume represents not just greater physical capacity but also strategic manufacturing power. This capability allows:

- Optimization of production planning

- Reduced supply chain dependency

- Cost-effective small-batch production

- Faster product development cycles

According to research published on ScienceDirect, companies utilizing large-format SLA systems achieve up to 40% time savings in production and reduce prototype costs by around 30%.

A New Era in Digital Manufacturing

SLA technology has become one of the cornerstones of digital transformation in manufacturing. Large build volume systems redefine the speed, flexibility, and efficiency of industrial production. This technology is no longer limited to prototyping but is also increasingly used in direct manufacturing.

Prodigma stands at the forefront of this transformation. Through its large-format SLA printing services, the company provides end-to-end support from design to mass production, contributing to the digitalization of production lines. Prodigma’s solutions enable precise, repeatable, and sustainable manufacturing across sectors such as automotive, aerospace, medical, tooling, and consumer electronics.

By partnering with an expert provider like Prodigma, companies not only embrace technological innovation but also improve production efficiency, lower costs, and significantly shorten product development cycles.

For faster, more precise, and sustainable manufacturing, SLA technology combined with Prodigma’s expertise delivers the competitive edge of the future, today. To learn more or discuss your custom production needs, you can reach out to the Prodigma team directly.