Sustainability

Prodigma is committed to leading the way in industrial digital manufacturing with a foundation in sustainability. Utilizing 3D printing and additive manufacturing technologies, we pledge to provide high-quality solutions to our customers while minimizing environmental impacts.

Sustainability is at the core of our business activities. From material selection to production processes, we focus on reducing environmental impacts at every step. We aim to lower our carbon footprint, reduce waste production, and increase energy efficiency. Compared to traditional manufacturing methods, 3D printing and additive manufacturing allow for more effective use of resources and minimize waste by using only the necessary amount of material. Additionally, by enabling custom designs and on-demand production, we prevent unnecessary stockpiling, thereby creating a sustainable supply chain.

At Prodigma, we are committed to not only delivering high-quality products to our customers but also prioritizing our environmental responsibilities, playing a sustainable role in the future of industrial digital manufacturing.

Circular Economy

Material Conservation: 3D printing can produce parts using only the required amount of material, preventing material waste compared to traditional manufacturing methods. This contributes to more efficient use of natural resources.

Personalized and Local Production: 3D printing supports localized and on-demand production, reducing energy consumption and the carbon footprint associated with long transportation and logistics processes.

Waste Reduction: Traditional manufacturing processes typically generate high amounts of waste. 3D printing, with its additive manufacturing principle, minimizes waste and allows for the production of only the necessary parts.

Remanufacturing: 3D printing facilitates the repair and reuse of used or old parts, extending product life and reducing the need for new materials.

On-Demand Production: 3D printing can operate according to a demand-driven production model, reducing the need for excessive inventory and preventing overproduction.

and

and

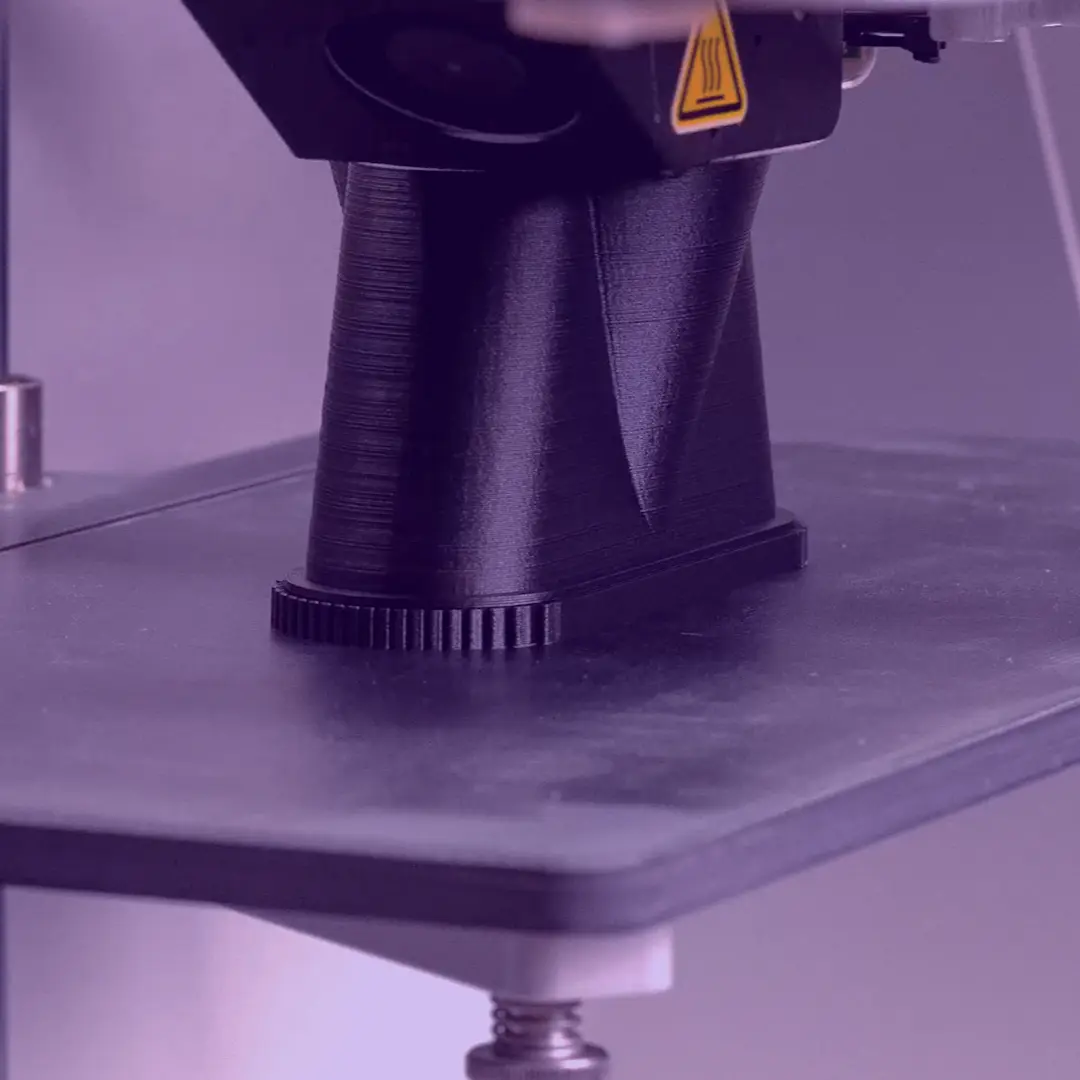

standards, we continuously review our business processes and focus on enhancing our efficiencies through the principle of continuous improvement.

standards, we continuously review our business processes and focus on enhancing our efficiencies through the principle of continuous improvement.