Fast Prototyping with Industrial 3D Printing: Save Time in Product Development;

In industrial manufacturing processes, speed, quality, and cost optimization are becoming increasingly important. At this point, industrial 3D printing offers significant advantages over traditional manufacturing methods, revolutionizing prototyping processes. In this article, we will discuss the impact of industrial 3D printing technology on fast prototyping, its benefits, and its applications in various industries in detail.

Industrial 3D Printing: Definition and Importance

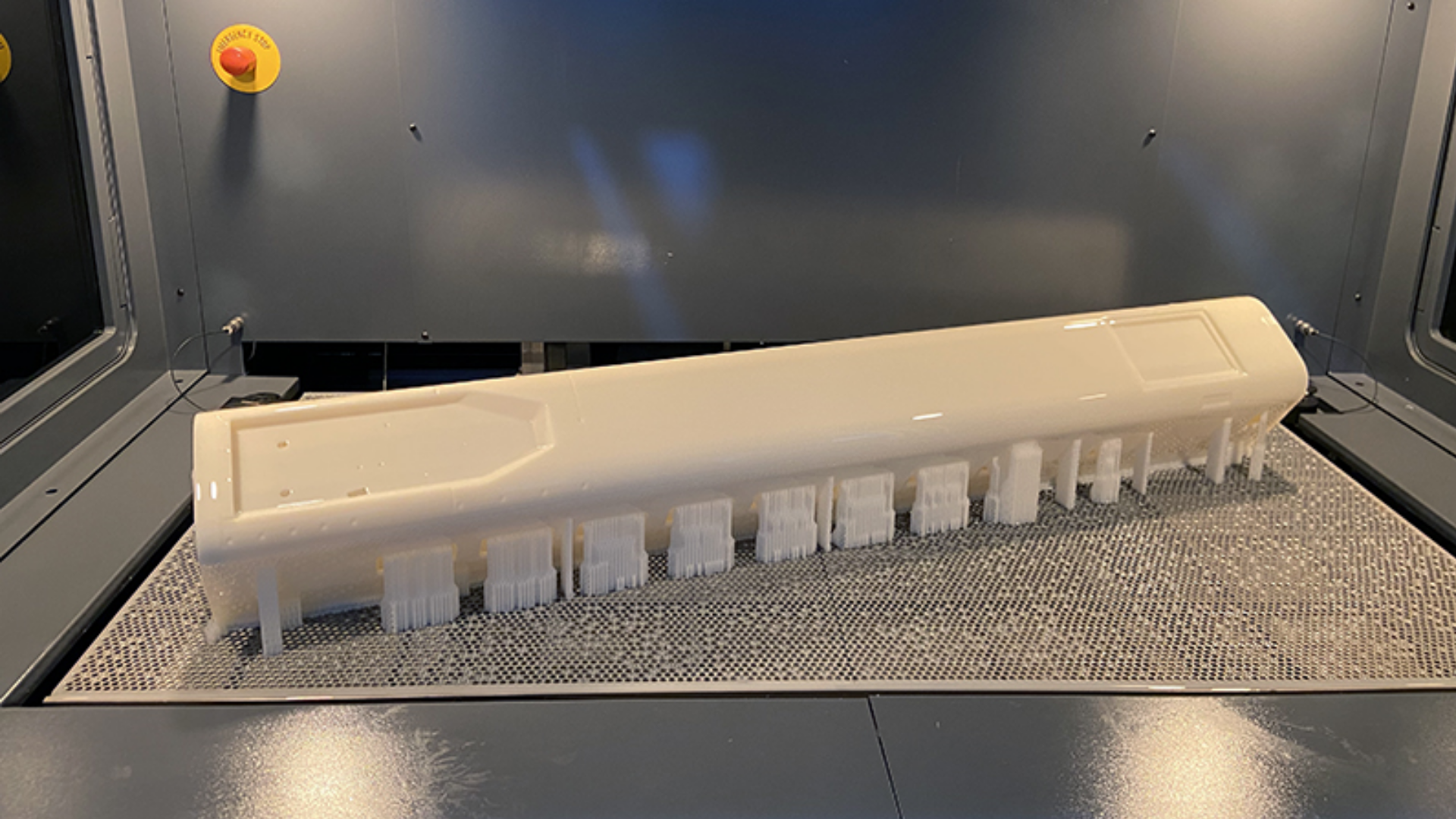

Industrial 3D printing is a manufacturing technology that directly converts digital models into physical objects. This technology adds material layer by layer, which provides a much faster and more flexible production process compared to traditional methods. Industrial 3D printers are typically large-scale machines designed to meet industrial standards.

Industrial 3D printing offers significant advantages, especially for quickly producing prototypes in the product development process. Traditional prototyping methods often involve several stages and time-consuming manufacturing processes, while 3D printing makes these processes much faster and more efficient.

Industrial 3D Printing Materials: Options and Benefits

Industrial 3D printing materials come in a wide range of options for various applications. These materials can range from plastics to metal alloys, and each material has its own specific advantages. Common materials include thermoplastics, metal powders, ceramics, and composite materials. Each material can be chosen based on the functional requirements of a specific product.

- Plastic Materials: Generally used for lightweight prototypes and quick testing.

- Metal Alloys: Ideal for industrial applications where metal parts are required. These are commonly used in the automotive and aerospace sectors.

- Ceramics and Composite Materials: Preferred for producing high-durability and heat-resistant products.

Industrial 3D printing offers production that provides both durability and aesthetics. Additionally, compared to traditional methods, it generates less waste, thus minimizing environmental impact.

Industrial 3D Printing Techniques: Which Methods Should Be Preferred?

Industrial 3D printing techniques vary depending on production requirements. Each technique offers different advantages and may be more efficient for certain industries. The most commonly used techniques include:

- Fused Deposition Modeling (FDM): One of the most widely used 3D printing methods, it uses plastic filaments to produce prototypes.

- Selective Laser Sintering (SLS): This technique uses laser to melt powder materials and shape them into durable and functional parts.

- Stereolithography (SLA): A technique that uses UV light to harden liquid resin layer by layer. It is ideal for applications that require high resolution and detailed production.

- Direct Metal Laser Sintering (DMLS): A technique that uses metal powders, especially for producing metal prototypes. It can produce high-durability metal parts.

Each industrial 3D printing technique is suitable for specific production goals. Therefore, selecting the right technique before starting the production process is crucial.

Industrial 3D Printing Machines: Efficiency in Production

Industrial 3D printing machines are high-capacity devices designed to speed up the production process. These machines provide high accuracy and speed in large-scale manufacturing. Additionally, they create minimal waste and require less labor during production.

Industrial 3D printing machines are capable of processing materials such as metal, plastic, or ceramics accurately. Their large size and speed allow large projects to be completed quickly.

Industrial 3D Printing and Its Applications: Sectoral Benefits

Industrial 3D printing and its applications have proven their worth in many sectors and are increasingly preferred. One of the biggest advantages of this technology is its ability to offer customized solutions for each industry. For example:

- Automotive Industry: 3D printing accelerates the product development process and provides flexibility between designs in part production and prototyping.

- Aerospace: 3D printing is used to produce lightweight, durable, and high-performance parts.

- Healthcare: This technology is widely used for producing customized products such as medical devices and prosthetics.

Industrial 3D printing not only allows for the fast production of prototypes but is also ideal for producing more functional and durable final products.

Industrial 3D Printing Service: Fast and Efficient Production with Prodigma

With the evolving technology, companies providing industrial 3D printing services are making production processes more efficient. Prodigma is leading the industry with its professional services in this area. Prodigma's industrial 3D printing solutions ensure high-quality results at every stage.

Prodigma's industrial 3D printing service allows for the quick production of prototypes and products tailored to customer demands. Additionally, high-efficiency production is achieved through tests conducted on the durability and functionality of the products.

By contacting Prodigma, you can perform your industrial 3D printing processes more quickly and efficiently.

Gaining a Competitive Advantage with Fast Prototyping

Industrial 3D printing provides businesses with significant advantages by speeding up prototyping processes. This technology allows high-quality prototypes to be produced at a lower cost while contributing to faster innovation. By working with Prodigma, you can make your industrial 3D printing process more efficient and accelerate your product development.

Remember, choosing the right technology and service not only improves your manufacturing processes but also increases your business's competitive strength. By using industrial 3D printing for fast prototyping, you can quickly bring your products to market and solidify your leadership in the industry.