What Advantages Does SLA Technology Offer Across Industries?;

In fields where traditional manufacturing methods fall short, 3D printing technologies have emerged as powerful alternatives in recent years. Among these, SLA (Stereolithography Apparatus) stands out with its precision, surface quality, and material flexibility—transforming manufacturing approaches across various industries.

In this article, we’ll explore what SLA technology is, how it works, and the unique advantages it brings to sectors such as automotive, healthcare, fashion, and architecture.

What is SLA Technology?

Stereolithography (SLA) is a 3D printing technology that builds three-dimensional objects by curing layers of photopolymer resin with a UV laser. Invented in 1986 by Charles W. Hull, SLA remains one of the most high-resolution 3D printing techniques available today.

The basic working principle of SLA involves:

- Directing a UV laser onto a tank filled with liquid resin,

- The laser traces each layer’s outline, instantly hardening the resin where it touches,

- As each layer is built up, the full 3D model is formed.

Thanks to its high accuracy and fine detail resolution, SLA is widely used in industrial prototyping and end-use part production.

Industries Transformed by SLA Technology

SLA contributes significantly to various sectors by accelerating production, reducing costs, and enabling innovative designs. Let’s take a closer look at the industries most impacted:

1. Automotive Industry

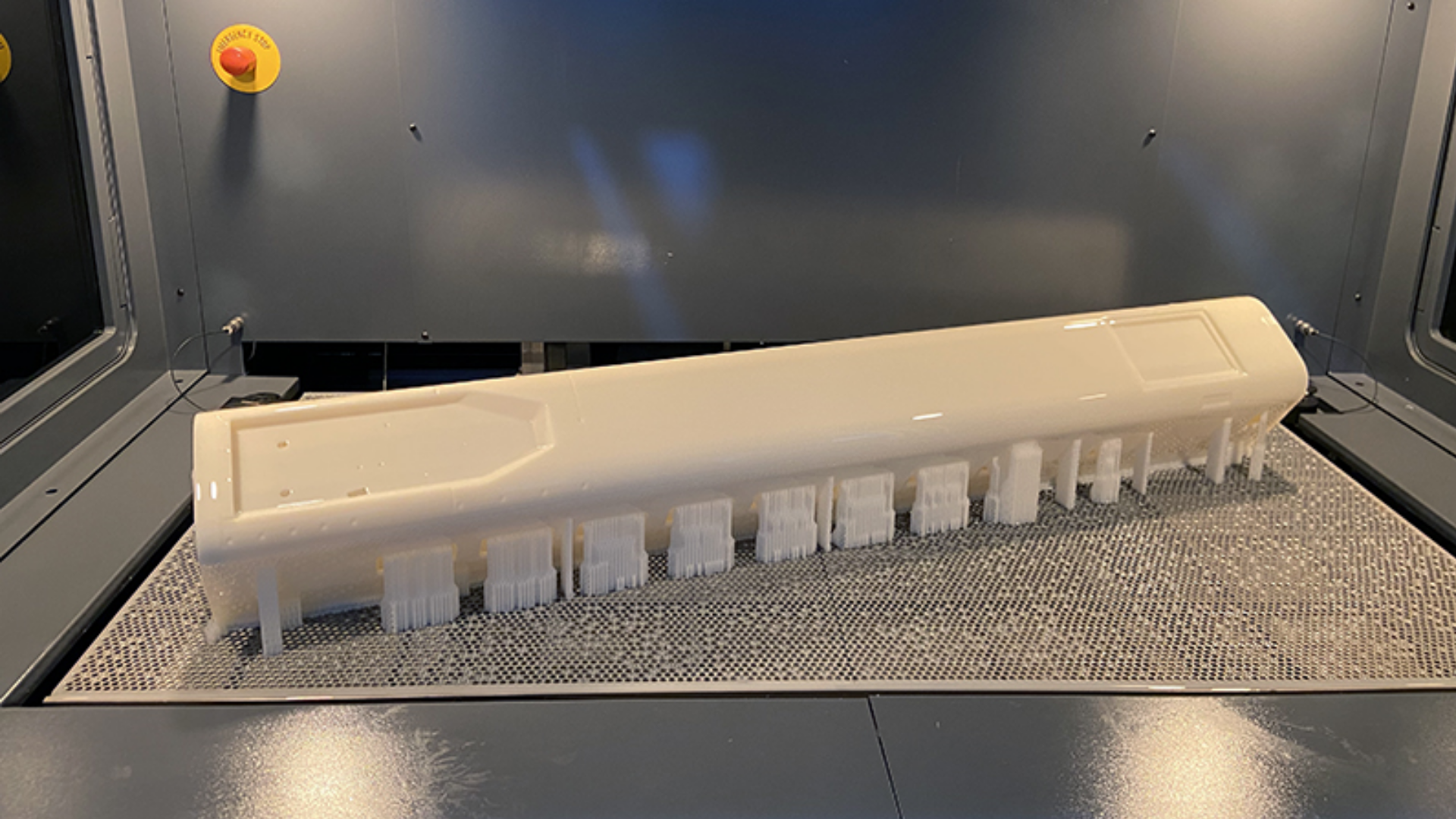

The automotive sector heavily relies on rapid prototyping during the development of new models. SLA printers play a critical role in this stage:

- Complex engine parts, body components, and interior elements can be printed at full scale quickly,

- Much faster and more cost-effective than traditional mold-making processes,

- Ideal for ergonomics testing, assembly analysis, and wind tunnel simulations,

- Auto parts suppliers can also deliver low-volume custom parts with high quality using SLA.

2. Healthcare and Medical Applications

One of the most impressive applications of SLA is in the medical field, where personalized solutions are essential:

- Dentistry: Custom orthodontic molds, implant guides, and models,

- Surgical Planning: 3D organ models derived from patient CT scans allow pre-surgical simulations,

- Orthotics and Prosthetics: Customized, anatomically correct parts for patients.

SLA’s detailed output and biocompatible material options are expanding its use in healthcare.

3. Jewelry and Fashion Industry

With its ability to print micron-level details, SLA has become a go-to tool for jewelry designers:

- Intricate designs for rings, necklaces, and earrings can be prototyped quickly,

- High-precision wax molds for casting reduce error margins,

- Replaces traditional hand-carving and mold-making with efficient digital workflows.

The fashion industry also leverages SLA to create original 3D-printed accessories and garment details.

4. Architecture and Construction

Architectural modeling is vital for presentations and client approvals. SLA provides:

- Fast production of detailed building, site, and infrastructure models,

- Designers can showcase physical models and collaborate using scale prototypes,

- Complex structures become easier to visualize and present.

SLA models are especially advantageous in urban design competitions, investor presentations, and municipal planning applications.

Core Advantages of SLA Technology

SLA 3D printers offer not only ease of production but also significant benefits in quality, efficiency, and creativity:

1. High Resolution and Detail

With layer thicknesses as low as 25 microns:

- Surfaces are smooth and clean,

- Complex geometries are printed without deformation,

- Minimal post-processing is required.

2. Material Flexibility

A wide variety of SLA-compatible resins are available today:

- Rigid, flexible, heat-resistant, and transparent options,

- Tailored mechanical properties for specific applications,

- Biocompatible resins for medical use.

3. Low-Volume and Customized Production

Unlike traditional mass production systems:

- SLA works efficiently even with low unit counts,

- Ideal for single or small-batch production,

- Custom solutions can be created to meet individual client needs.

High Efficiency with SLA Technology by Prodigma

If your business seeks high-quality, rapid, and customized production solutions, Prodigma’s SLA offerings are worth exploring. Prodigma provides:

- High-resolution SLA printer models,

- Technical consulting tailored to industry needs,

- Support throughout both production and prototyping phases.

For more details, visit the Prodigma website or connect directly with their expert team via the contact page.

SLA's Role in Industrial Transformation

SLA technology is one of the most vital tools shaping the future of manufacturing. With advantages like precision, speed, flexibility, and cost-effectiveness, it is now actively used across industries from automotive to healthcare.

By adopting SLA correctly, businesses can:

- Shorten product development cycles,

- Offer personalized production,

- Gain a competitive edge.

With a reliable partner like Prodigma, it’s now easier than ever to unlock the full potential of SLA 3D printers and digitize your production processes. Contact us today to receive your custom solution.