Sustainable Production with 3D Printing: Energy and Material Savings;

In today’s world, sustainable production is crucial not only for environmental reasons but also for energy efficiency and resource management. One of the most impactful tools in industrial transformation is 3D printing, which offers innovative and effective solutions in this regard. Especially in production processes, reducing unnecessary waste and enabling customized manufacturing has a groundbreaking impact on environmental sustainability.

How Does 3D Printing Contribute to Sustainability?

Compared to traditional manufacturing methods, 3D printing technologies offer the following advantages:

- Reduction in Material Waste: Only the necessary amount of material is used, preventing the excess waste that occurs in methods like injection molding.

- Energy Efficiency: With fewer energy-intensive processes in part production, manufacturing processes leave a smaller carbon footprint.

- Localized Production: By reducing the need for imports and exports, logistics-related emissions are minimized.

- Use of Recyclable Materials: Biodegradable filaments like PLA contribute to environmental sustainability.

- According to research, 3D printers can use up to 90% less material for some parts compared to traditional methods (source: sciencedirect.com).

The Role of 3D Printing Machines in a Sustainable Future

The use of 3D printing machines in modern manufacturing lines is steadily increasing. These machines accelerate processes from prototyping to final product production while minimizing environmental impacts. They offer energy-saving solutions, particularly in sectors like:

- Automotive,

- Healthcare,

- Architecture,

- Fashion.

Choosing Energy-Efficient 3D Printing Services

When selecting 3D printing services for corporate and individual manufacturers, it is important to choose solutions that offer energy and resource savings. Key criteria to consider:

- Type of material used (recyclable or biodegradable),

- Energy class and machine efficiency,

- Waste recycling processes,

- Localized production capabilities (reduces carbon emissions).

Prodigma develops sustainable solutions with these criteria in mind, providing users the opportunity to make informed choices. You can explore more about 3D printing solutions with us.

Effective 3D Printing Techniques in Eco-friendly Manufacturing

3D printing techniques vary depending on the technology used and the manufacturing purpose. Each technique offers specific sustainability benefits:

- FDM (Fused Deposition Modeling): The most common and cost-effective technique. It uses biodegradable filaments and is environmentally friendly.

- SLA (Stereolithography): Ideal for detailed parts, although resin-based materials need to be used carefully.

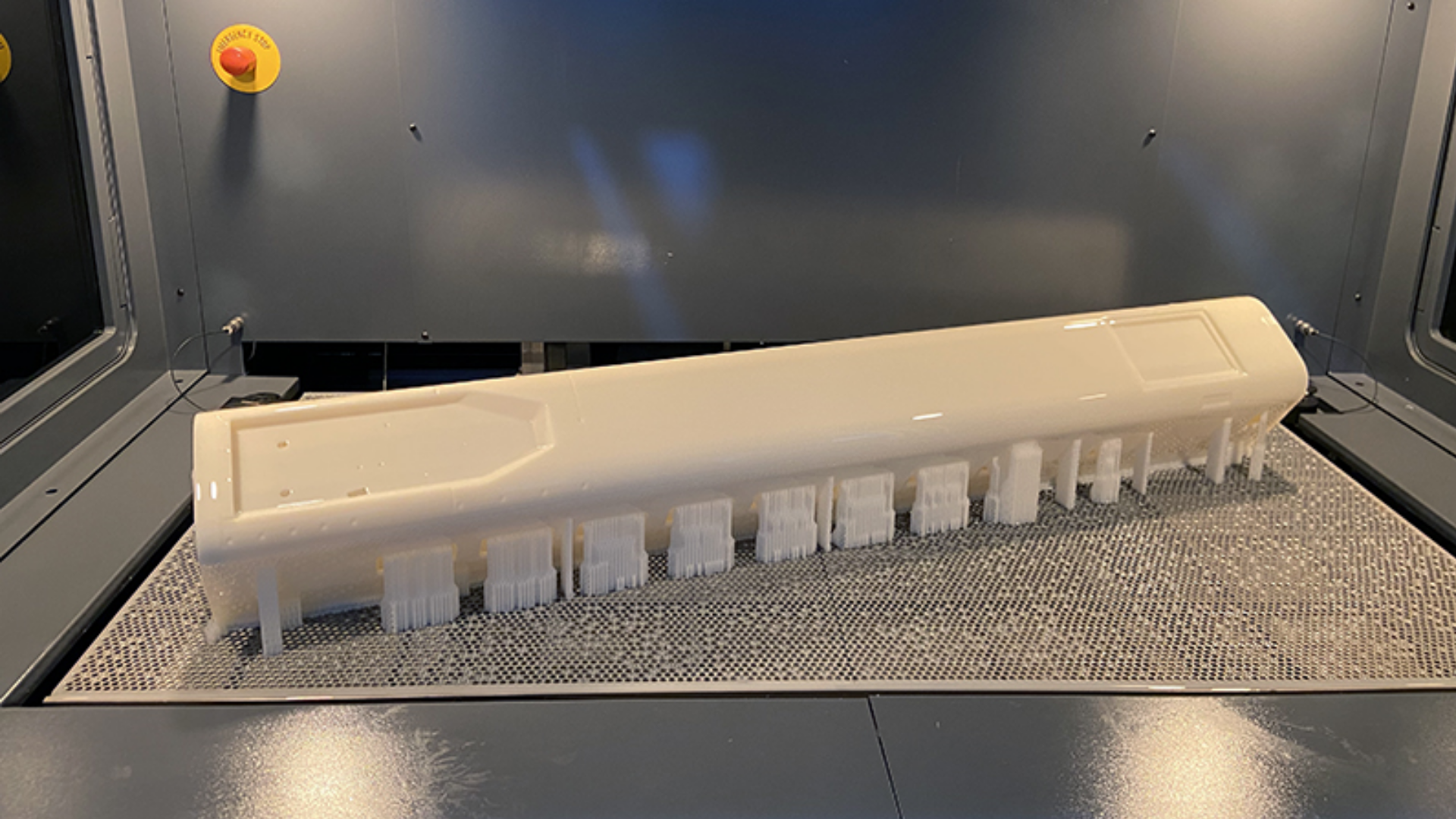

- SLS (Selective Laser Sintering): Provides high durability with powder-based production and can use recyclable powders.

Sustainable 3D Printer Products

Today, many manufacturers are developing 3D printers that have less environmental impact. These include:

- PLA Filaments: Plant-based and biodegradable.

- Recycled Filaments: Made from processed old prints.

- Energy-efficient Printer Models: Printers that consume less energy during printing.

Prodigma’s eco-friendly 3D printer products help users reduce their carbon footprint.

Why and How Should You Opt for 3D Printing?

The 3D printing process offers personalized manufacturing opportunities, reducing waste and shaping production processes in an eco-friendly way. To manage this process sustainably:

- Choose local manufacturers for services,

- Produce using minimum materials tailored to the need,

- Use recyclable materials.

For comprehensive and environmentally-friendly solutions, you can contact Prodigma.

Long-Term Value: What to Consider When Choosing 3D Printing Services

When selecting 3D printing services, the manufacturer’s sustainability approach, technical infrastructure, and energy management strategies are of critical importance. Key factors to consider include:

- Quality and sustainable material supply,

- Transparent waste management policies,

- Carbon footprint reporting,

- User-friendly, low-energy consuming equipment.

The Future of Sustainable Manufacturing is Shaped by 3D Printing

The future of manufacturing models is now evaluated not only for efficiency but also for their impact on nature and people. 3D printing is at the center of this transformation, preserving resources while supporting innovation. It allows for personalized solutions while saving energy and materials.

If you want to transform your production processes with an eco-friendly approach, meet Prodigma, the leader in sustainable technologies. Shaping the future is in your hands.