The Role of 3D Printing in the Project;

“The Electromyogram-Stimulated Robotic Hand Rehabilitation System project, led by MAREL R&D, offers an innovative solution for restoring hand function after stroke or injury. Developed with Prodigma’s 3D printing contributions, the smart glove enables independent rehabilitation while providing high accuracy and cost advantages. This project is seen as an important step toward making robotic rehabilitation applicable at home and widespread in the healthcare sector.”

The Future of Robotic Rehabilitation and 3D Printing: The Electromyogram-Triggered Robotic Hand Rehabilitation System Project

Today’s rapidly evolving technologies are driving significant transformations, especially in the healthcare sector. One of the most impactful innovations in this field is robotic rehabilitation systems. The Electromyogram (EMG)-Triggered Robotic Hand Rehabilitation System Development project, conducted by MAREL ARGE, introduces an innovative approach to restoring hand function after a stroke or injury through the use of robotic hand orthoses. The project’s developed smart glove and EMG-triggered rehabilitation system allow elderly patients, in particular, to carry out their rehabilitation independently at home.

This project not only aims to restore hand and finger functions but also reduces dependence on hospital settings and physiotherapists by offering a treatment that can be applied at home. The smart glove, with features such as mirror therapy and EMG-triggered rehabilitation, allows patients to perform repetitive and intensive exercise programs wherever they choose. As the workload on hospitals and physiotherapists increases, the demand for such systems is growing daily. The portability and sensor-equipped design of the developed prototype help accelerate the rehabilitation process while also improving patients' quality of life.

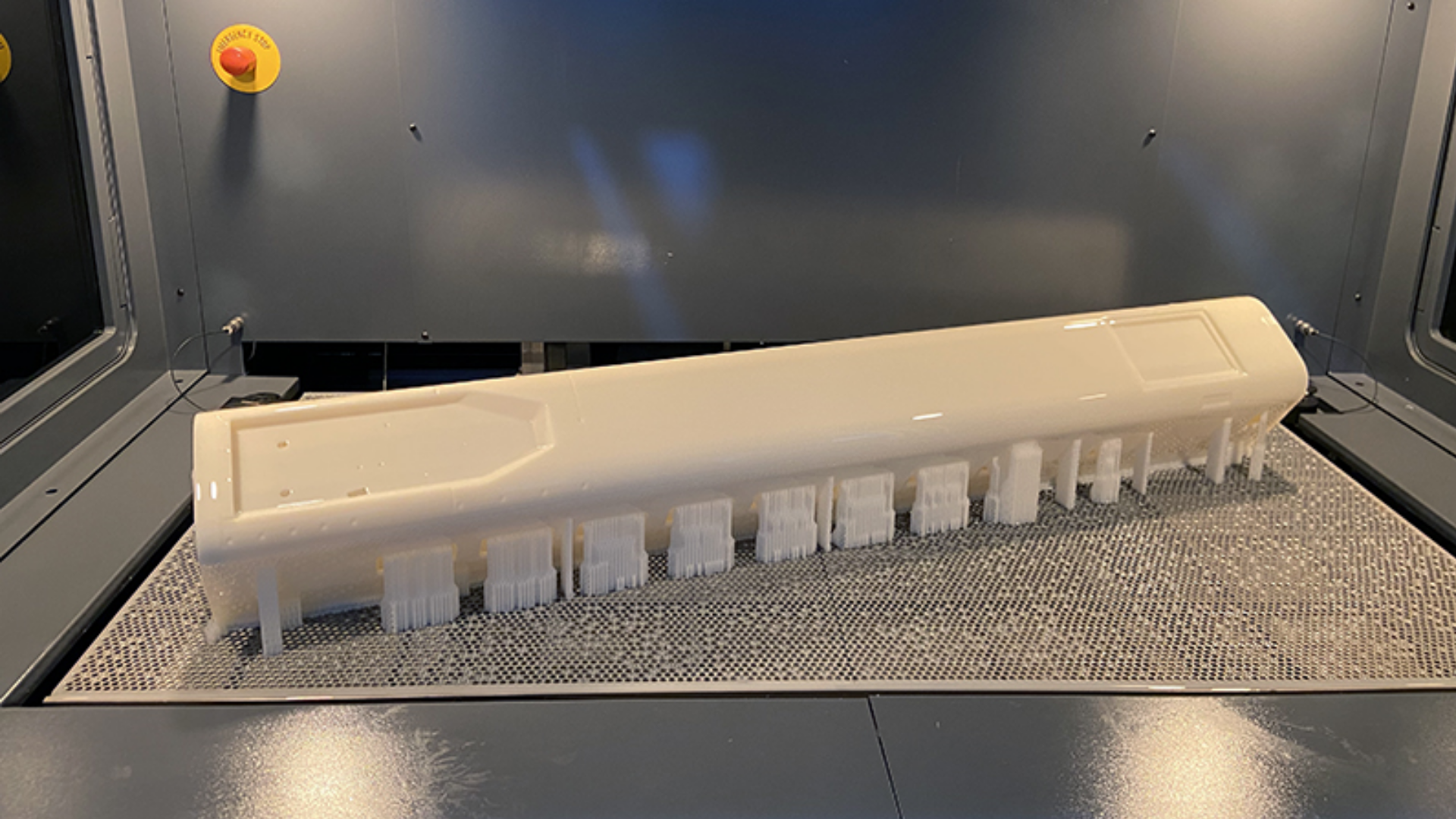

The Role of 3D Printing in the Project

At Prodigma, our contribution to the project lies in the use of 3D printing technology to produce critical parts of the smart glove. The integration of sensors within the 3D-printed parts significantly improved the product’s quality, reduced costs, and shortened production times. The flexible TPU material used in the project ensures that the glove fits perfectly on the fingers and facilitates the accurate transmission of data from the angle sensors. This capability is crucial for monitoring finger positions precisely during rehabilitation exercises.

3D printing technology stands out in this project by providing considerable advantages in terms of time and cost savings. It eliminates the need for molding costs and enables the rapid production of the required prototypes. Additionally, the ability to quickly bring aesthetic designs to life added an innovative dimension to the project. The integration of sensors into the printed components enhanced the functionality of the device while speeding up its transition to a professional final product.

The Electromyogram-Triggered Robotic Hand Rehabilitation System Development project successfully merges robotic technologies with 3D printing to offer innovative solutions in hand rehabilitation. The project not only simplifies independent rehabilitation processes for patients but also demonstrates the immense potential of 3D printing technology in the healthcare sector. With the continued adoption of the smart glove and system in the future, robotic rehabilitation at home is set to become a standard treatment method. At Prodigma, we are proud to contribute to this transformation in healthcare and will continue to support technological advancements through our 3D printing solutions.