The Role of 3D Modeling in Reverse Engineering: Fast and Accurate Results;

Reverse engineering refers to the process of thoroughly analyzing an existing product to better understand its design and production processes. One of the most essential tools in this field is 3D modeling technology. By enabling the creation of a three-dimensional digital representation of a physical object, 3D modeling bridges the gap between the physical and virtual worlds. In recent years, the relationship between reverse engineering and 3D modeling has revolutionized product design and development. In this article, we explore the role of 3D modeling in reverse engineering and how it enables fast and accurate results.

What is 3D Modeling?

3D modeling is the process of creating a digital representation of a physical object using CAD (Computer-Aided Design) software. Each modeling program offers distinct tools suited for specific applications. 3D modeling is widely used across industries such as engineering, architecture, game design, and manufacturing. In the context of reverse engineering, 3D modeling enables faster identification and correction of design flaws while accelerating improvement processes.

These techniques allow for the creation of highly detailed digital models that fully reflect the geometric properties of an object, making it easier to analyze, measure, and redesign physical components.

How is 3D Modeling Done?

The question “How is 3D modeling done?” lies at the heart of engineering and design processes. The typical steps in 3D modeling for reverse engineering are:

- Scanning and Data Collection:

The process begins with capturing the physical dimensions of an object using technologies such as laser scanning or photogrammetry.

- Using 3D Modeling Software:

The collected data is transferred to specialized software that processes the 3D data and creates a digital model of the object.

- Model Review and Refinement:

The generated model is evaluated for accuracy and functionality. Adjustments are made as necessary.

- Preparing for 3D Printing (if applicable):

If the goal is to produce a physical prototype, the model is optimized for 3D printing to avoid errors during production.

3D Modeling Software and Applications

A variety of 3D modeling tools are used in engineering and design. Each offers different capabilities based on user needs. Popular programs include:

- AutoCAD: Widely used in engineering and architecture for designing complex geometries.

- SolidWorks: A powerful tool for mechanical engineering and 3D design.

- Blender: A free, open-source program also used for animation and visualization.

- Fusion 360: A cloud-based solution integrating engineering and design workflows.

These platforms play a key role in reverse engineering and product modeling. Their feature diversity enables users to choose the most appropriate solution for their specific applications.

Examples of 3D Modeling in Reverse Engineering

3D modeling is commonly used in reverse engineering workflows. For example, in the automotive industry, a component may be 3D scanned and digitally reconstructed. Engineers then analyze the digital model and implement design improvements.

This process helps reduce manufacturing costs, minimize errors, and shorten development timelines. It also eliminates the need for physical prototypes by enabling fast digital testing of designs.

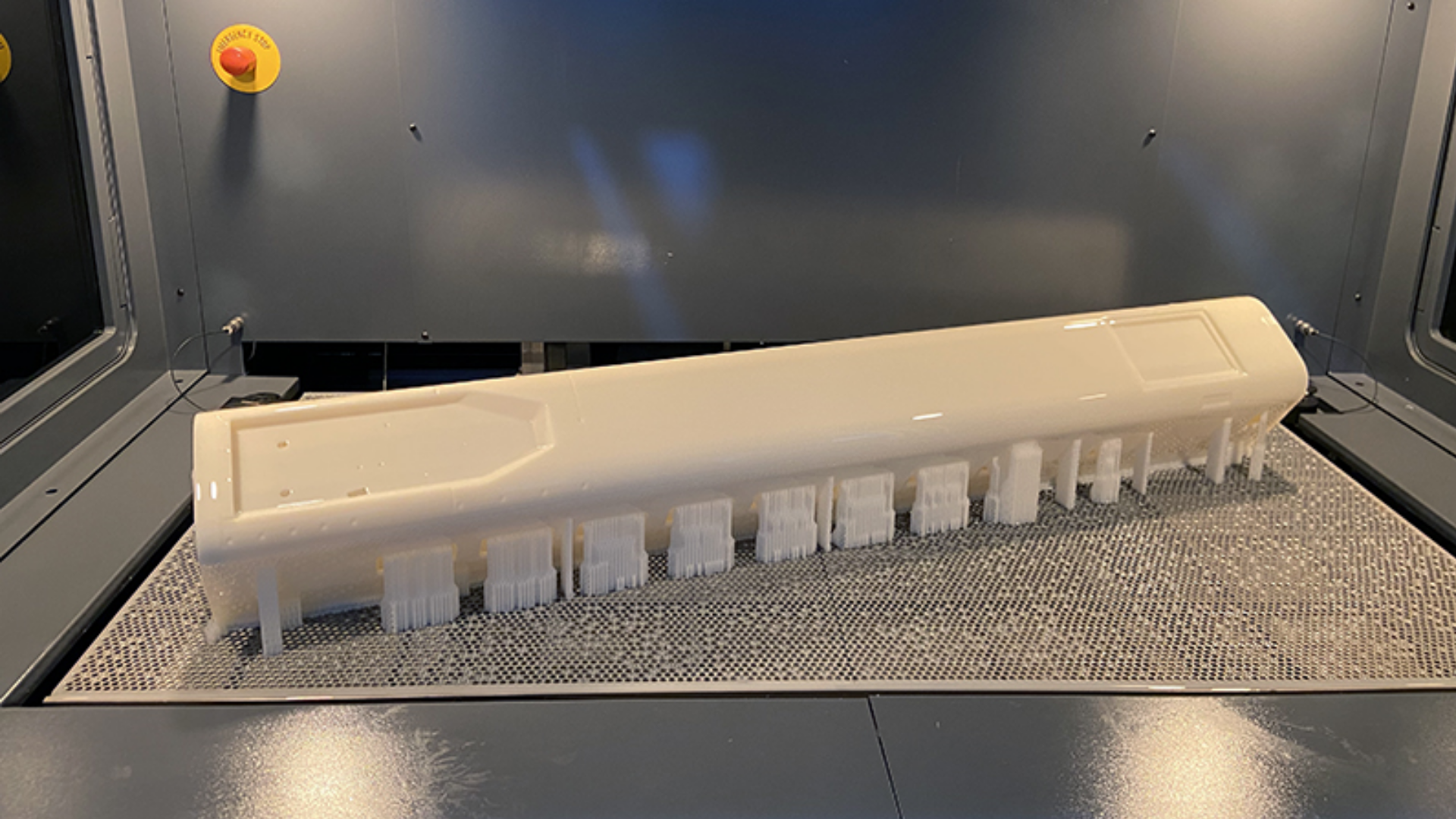

3D Printing and Reverse Engineering

3D printing is another vital technology often used alongside 3D modeling in reverse engineering. It enables physical reproduction of digital models layer by layer. Prototypes of scanned objects can be created quickly, allowing engineers to detect design flaws early in the process.

Prototypes produced with 3D printing help designers evaluate parts physically, offering a significant advantage in refining and finalizing designs.

Applications of Reverse Engineering and 3D Modeling

Reverse engineering and 3D modeling are widely used in industries such as industrial design, automotive, aerospace, construction, and healthcare. These techniques allow for the reproduction of worn or obsolete parts. The integration of various technologies across sectors helps create more efficient production processes.

Prodigma provides solutions that simplify 3D scanning and reverse engineering. The company supports industrial and production-focused projects with fast and accurate results.

Efficient and Precise Design Through 3D Modeling

3D modeling significantly contributes to achieving faster and more accurate results in reverse engineering. From product design to production, this technology offers major advantages.

Products can be digitally recreated with unprecedented precision, enabling early detection of design flaws and cost reduction. Reverse engineering combined with 3D modeling transforms production and engineering workflows, offering manufacturers a clear competitive edge.

With Prodigma’s expert solutions, these processes become even faster and more efficient.

3D modeling plays a crucial role not only in engineering and design, but also in manufacturing and post-production services. It offers professionals across all industries the opportunity to achieve efficient and accurate results.

If you would like to learn more about 3D modeling and its applications, you can get in touch with Prodigma today.