New Materials Used in Additive Manufacturing;

Additive manufacturing offers many advantages compared to traditional production methods. These advantages include design freedom, reduced material waste, and rapid prototyping. However, one of the most significant advancements in this technology is the diversity and innovations in the materials used. In this article, we will focus on new generation materials used in additive manufacturing, such as composites, metal powders, and bioplastics, and we will compile the advantages and disadvantages of these materials for you.

Composite Materials

Composite materials consist of a combination of two or more different materials. These materials perform at a high level thanks to their combined properties. In additive manufacturing, composite materials typically consist of two components: a matrix and a reinforcement material. The matrix is usually a polymer, while the reinforcement material can be high-strength materials such as carbon fiber, glass fiber, or Kevlar. You can review the composite materials available at Prodigma below:

· KEVLAR™

· FIBERGLAS™

· HSHT FIBERGLAS™

· CARBON FIBER™

· CARBON FIBER FR-A™

Composite materials are highly attractive, particularly in the aerospace and automotive industries, due to their high strength-to-weight ratio. The properties of composites can be customized by using different reinforcement materials, allowing for the creation of the ideal material for specific applications. Additionally, composite materials generally have high corrosion resistance, making them suitable for use in harsh environmental conditions.

The production costs of composite materials are higher compared to traditional materials. Furthermore, the use of these materials in additive manufacturing requires special equipment and expertise, making the production process complex. However, at Prodigma, you can eliminate these disadvantages by uploading your CAD file, making your selections, and receiving an instant price quote to place your order.

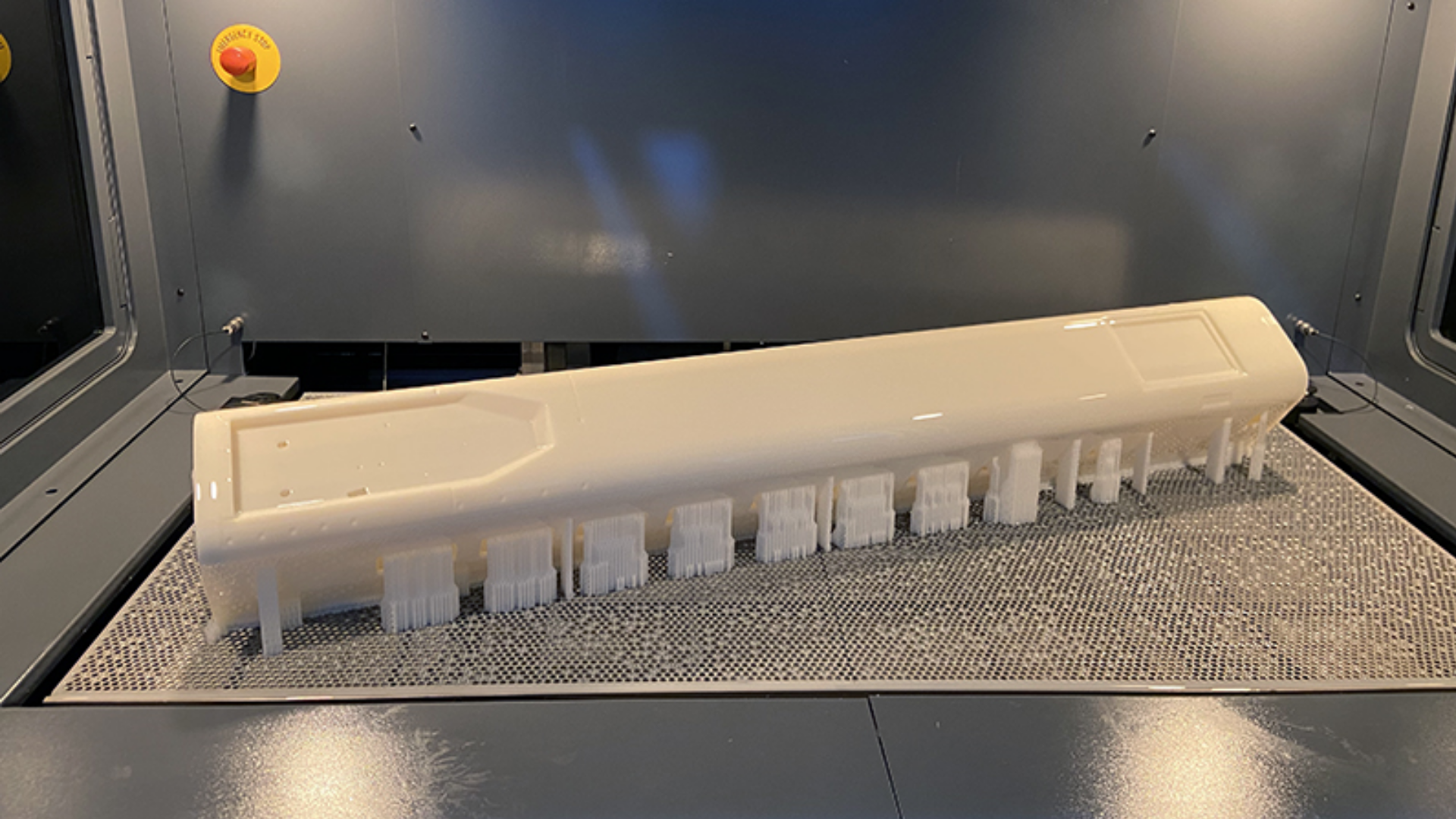

Photopolymers

Photopolymers are known as light-curing resins and are typically used in stereolithography (SLA) and digital light processing (DLP) technologies. These materials harden and solidify when exposed to UV light. You can review the photopolymer materials available at Prodigma below:

· xMODEL15

· xMODEL35

· 3843ABS BLACK

· xMOLD

· xPEEK147

· xESD

· XFLEX402

· xCERAMIC3280

· ABS like WHITE

· ABS like BROWN

· CLEAR

Photopolymers provide high levels of detail and smooth surfaces, making them ideal for small and complex parts. Their ability to harden quickly with light shortens the production time. Additionally, they can have various properties, such as flexibility, rigidity, or transparency, offering a wide range of applications. Photopolymers generally do not have long-term mechanical durability and may degrade over time when exposed to UV light. High-quality photopolymer resins are usually expensive. Furthermore, the material options for photopolymers are limited and often require customized materials for specific applications.

Thermoplastics

Thermoplastics are plastics that soften when heated and harden when cooled. Commonly used thermoplastics in additive manufacturing include ABS (acrylonitrile butadiene styrene), PLA (polylactic acid), and PETG (polyethylene terephthalate glycol). You can review the thermoplastic materials available at Prodigma below:

· ONYX™

· ONYX FR™

· ONYX FR-A™

· ONYX ESD™

· Nylon™

· P-PLA™

· TPU 82A

· S-TPU™

· PEEK

· PEKK

· PEI

· VEGA™

Thermoplastics are suitable for additive manufacturing because they can be easily melted and shaped. They can be used in a wide range of applications, from automotive to medical devices. Additionally, they can be melted and reused, providing recycling opportunities and enhancing sustainability. Thermoplastics generally do not have as high mechanical properties as metals or composites and may not be suitable for certain applications. Specifically, their resistance to high temperatures is limited, making them unsuitable for certain industrial processes and harsh environmental conditions. However, the thermoplastics available at Prodigma are made from strong materials used in the aerospace industry that exhibit high resistance to fire, heat, and chemicals. These special thermoplastics overcome the disadvantages of conventional thermoplastics and can be used safely in various challenging applications.

Metal Powders

Metal powders are another important material group used in additive manufacturing. These powders are fused layer by layer using techniques such as laser sintering or electron beam melting to create parts. The most commonly used metal powders include titanium, aluminum, and stainless steel.

Parts produced from metal powders generally have high strength and durability. Metals are known for their high thermal and electrical conductivity, making them ideal for electronic and automotive applications. Additionally, metal powders can be recycled in the production process, reducing material waste and promoting sustainability. The cost of high-quality metal powders is quite high. Furthermore, processing metal powders requires special equipment and expertise, making the production process complex and costly.

Bioplastics

Bioplastics are plastics derived from biological sources and are biodegradable. Commonly used bioplastics in additive manufacturing include PLA (polylactic acid) and PHA (polyhydroxyalkanoate).

Bioplastics are environmentally friendly because they are biodegradable. They reduce dependence on fossil fuels as they are derived from renewable resources. Additionally, bioplastics are generally low in toxicity, making them suitable for food and medical applications. Bioplastics have lower mechanical properties compared to traditional plastics. Furthermore, the production costs of bioplastics are higher, and they are less resistant to harsh environmental conditions.

The new generation materials used in additive manufacturing, including composites, metal powders, bioplastics, photopolymers, and thermoplastics, each offer significant innovations with their own advantages and disadvantages. Composites provide high strength and lightweight properties, while metal powders offer superior mechanical properties and conductivity. Bioplastics stand out as environmentally friendly materials derived from renewable resources. Photopolymers provide high resolution and detail, while thermoplastics offer a wide range of applications and ease of processing. The correct selection and use of these materials are critical to maximizing the potential of additive manufacturing.