The Manufacturing Technology of the Future: Which Industries Are Being Transformed by 3D Printing?;

In the era of digital transformation, manufacturing techniques are rapidly evolving. At the forefront of this revolution stands 3D printing, which is not only disrupting prototyping processes but also revolutionizing final product manufacturing. Once confined to limited applications, this technology is now reshaping industries ranging from automotive to healthcare, fashion to construction.

What Is 3D Printing?

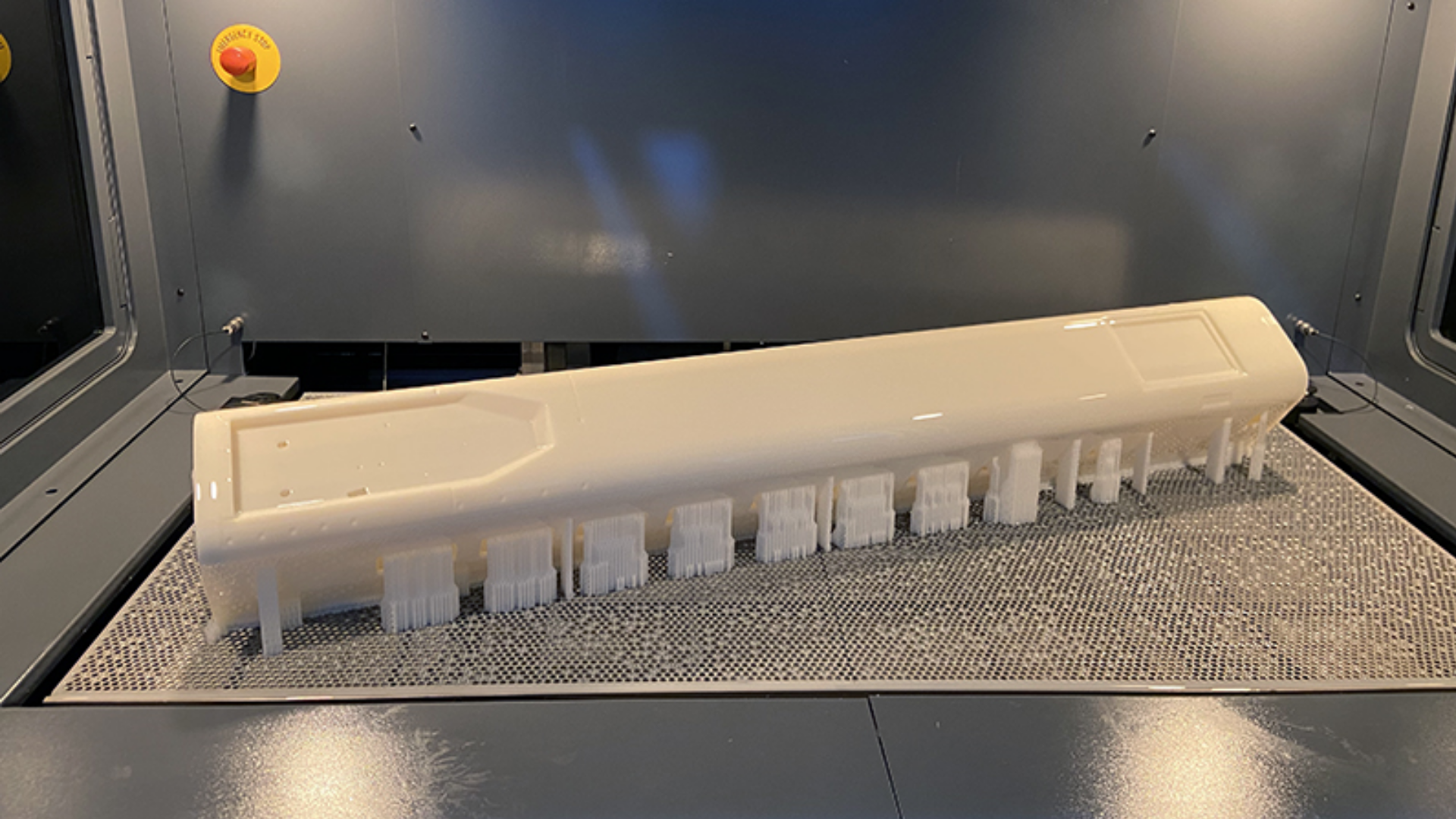

3D printing is a manufacturing technology that builds a physical object layer by layer from a digital model. Using Computer-Aided Design (CAD), digital models are created and then transformed into three-dimensional objects using materials such as plastic, metal, resin, or biomaterials. Unlike traditional production methods, 3D printing offers greater flexibility and generates significantly less waste.

In Which Fields Are 3D Printed Products Used?

Today, 3D printed products are not only used for prototyping but also appear in a wide range of end-user applications. Key sectors include:

- Healthcare: Customized prosthetics, implants, anatomical models

- Aerospace & Defense: Lightweight engine parts, specialized components

- Architecture: Scaled building models, construction elements

- Fashion & Jewelry Design: Unique jewelry, shoe molds

- Consumer Electronics: Phone cases, drone components

Prodigma provides innovative, customizable, and functional 3D printing solutions that contribute to transformation across these industries.

What Materials Are Used in 3D Printers?

As 3D printing technology advances, the variety of materials used has significantly expanded. Common materials include:

- Thermoplastics (ABS, PLA): Durable and cost-effective

- Resins: Ideal for detailed, high-resolution models

- Metal powders (Aluminum, Titanium): Used in aerospace and automotive

- Composites (Carbon fiber-infused): Provide high strength and low weight

- Biomaterials: Used in customized healthcare applications

Material selection depends on the intended use of the product, and choosing the right material directly affects the quality of the final print.

Industrial Transformation with 3D Printed Products

3D printers eliminate the limitations of traditional manufacturing by offering flexibility, cost-efficiency, and rapid production in industrial settings. Especially in sectors requiring low-volume or customized production, the impact is significant.

Key Industries Undergoing Transformation:

- Automotive: Complex engine parts, interior design components

- Healthcare: Personalized medical solutions based on patient data

- Education: Prototypes that allow students to experience design processes

- Defense: Rapid and durable production of mission-critical parts

According to Harvard Business Review, the customization capabilities of 3D printers can reduce product development time by up to 60% (HBR.org).

Time and Cost Savings with 3D Printers

3D printers minimize the time losses caused by traditional methods like molding and milling. Instead of creating new molds for each product, manufacturing is performed directly from a digital file.

Advantages:

- Minimal material waste

- Low production costs

- Fast prototyping and manufacturing

- Custom product development

- Remote production and on-site printing

Prodigma helps businesses optimize these processes through tailored industrial solutions. For more information, you can get in touch with Prodigma directly.

3D Printing Models: The Design Libraries of the Future

3D printing models make rapid production possible for designers, engineers, and manufacturers through digital libraries offering ready-to-use or customizable CAD files.

Popular Application Areas:

- Industrial prototypes

- Architectural models

- Medical training models

- Educational materials

- Decorative home items

You can also benefit from Prodigma’s custom modeling services to access solutions tailored to your specific 3D printing needs.

The Future of Manufacturing with 3D Printers

With the rise of Industry 4.0, 3D printing technology has become a cornerstone of autonomous manufacturing systems. It is also transforming logistics by enabling on-site production. This is particularly critical in disaster zones or remote areas.

For example, the World Food Programme (WFP) used 3D printing to produce medical tools directly in disaster areas, reducing logistical burdens by up to 30% (wfp.org).

Why Choose Prodigma?

Based in Turkey, Prodigma offers innovative 3D printer solutions tailored to a wide range of sectors. From prototyping to end-use product manufacturing, the company stands out with its engineering-driven, customizable services.

Prodigma's Advantages:

- Project-based custom modeling services

- Industrial-grade printing capacity

- Technical consulting and support

- High-quality printing materials

Invest in the Future Today with 3D Printing

3D printed products are not only transforming today’s manufacturing landscape but also shaping the future of production. Focused on sustainability, speed, and customization, this technology offers businesses a significant competitive edge.

By partnering with Prodigma, you can become a part of this transformation and boost your manufacturing capabilities with tailored solutions.