The Impact of 3D Printing on Industrial Manufacturing Processes: Mass Production and Customized Product Manufacturing;

Traditional manufacturing processes, especially in large-scale mass production, rely on repeated production steps with high fixed costs. The production of molds and tools in this process leads to significant expenses and long lead times. However, in recent years, 3D printing technology (also known as additive manufacturing) has begun to transform industrial manufacturing processes significantly. This technology not only enhances efficiency in mass production but also makes the manufacturing of customized products more economical and faster.

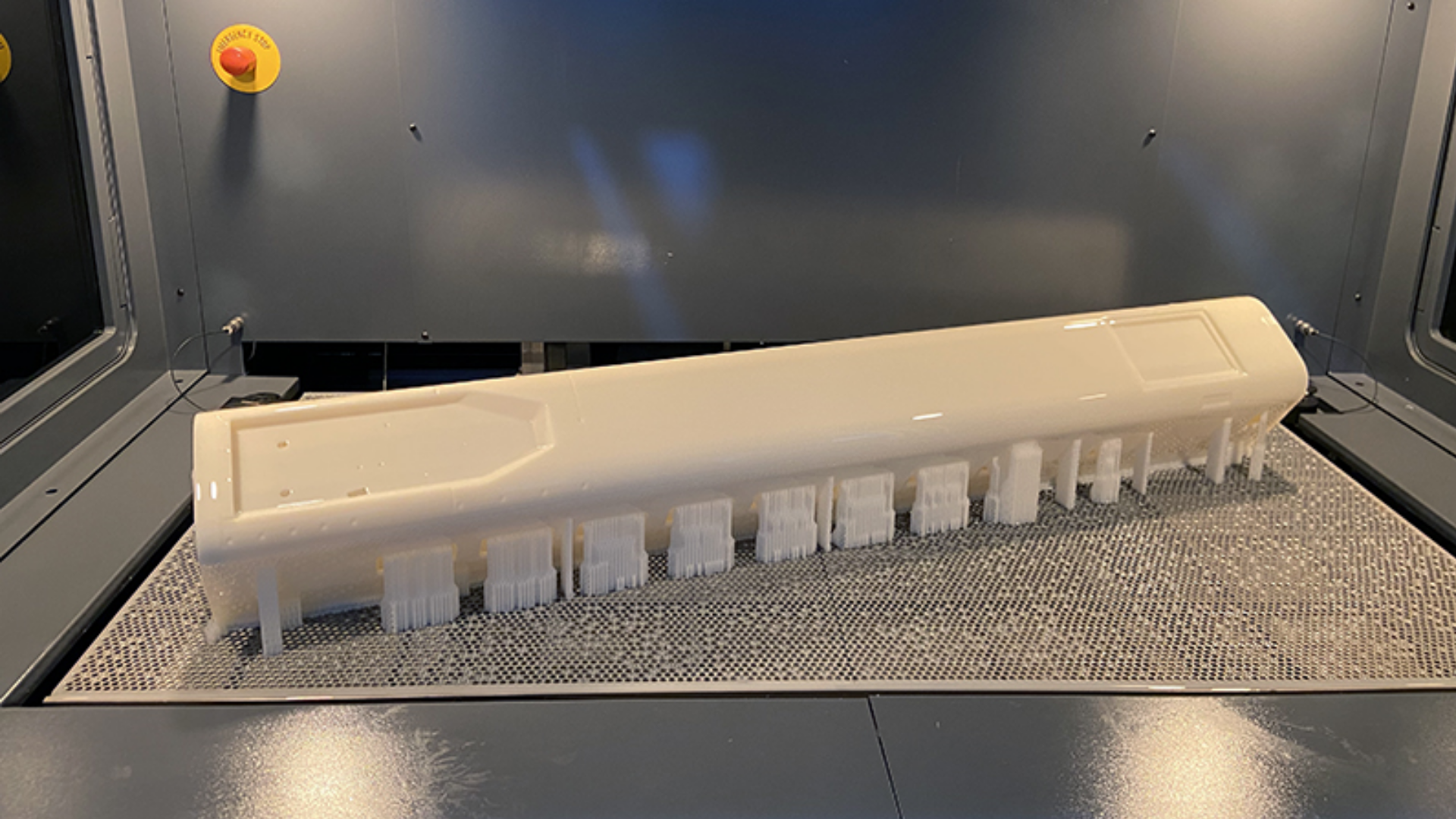

3D printing accelerates the production process by eliminating the need for molds and fixed tools. Techniques like Powder Bed Fusion (PBF) and Selective Laser Sintering (SLS) produce complex parts by sintering or melting layers of material using lasers. These methods are particularly preferred in production with durable materials such as metals and high-performance polymers. In traditional manufacturing processes, multiple assembly and joining steps are required to produce a part, whereas 3D printing technology enables completion in a single production step. For example, the fuel injectors used in Ariane 6 rocket engines, which previously required assembly of 248 separate parts, can now be produced as a single part using 3D printing technology. This significantly reduces not only production costs but also production times, while allowing for design optimization.

Another major impact of 3D printing on industrial manufacturing is its ability to produce customized products at low cost and with high flexibility. In traditional methods, customizing a product often involves high costs and long production times. Particularly, the production of molds is a factor that increases costs and limits flexibility. However, with 3D printing technology, each product can be digitally designed and customized without any additional costs. This presents a significant advantage in fields requiring personalized production, such as medical devices, dentistry, and prosthetics. For example, orthopedic implants produced using 3D printing technology can be custom-made to fit patients' anatomy, reducing surgery time and speeding up recovery. Additionally, in the automotive industry, the use of 3D printing for spare parts and low-volume production is increasing. Mercedes-Benz, for instance, uses 3D printing technology to produce hard-to-find spare parts for classic vehicles on demand.

Despite all these advantages, there are some technical and economic challenges that hinder the widespread adoption of 3D printing in industrial manufacturing. Especially, making materials like metal powders suitable for 3D printing is more expensive than traditional materials. Additionally, the production speeds of 3D printing machines are not fast enough for large-scale production. To increase production speed and reduce printing costs, it is necessary to develop new materials and optimize production processes.

In conclusion, 3D printing technology has led to a significant transformation in industrial manufacturing processes. Advantages such as reduced costs, accelerated production processes, and the easy production of customized products make this technology attractive. However, challenges related to speed, material costs, and large-scale use need to be addressed for the full adoption of 3D printing. Future technological developments and innovations in new materials may help overcome these obstacles, enabling wider use of 3D printing in both mass and customized manufacturing.