How to Enhance Sustainability in Digital Manufacturing with Printing Services?;

Printing Services: The Silent Hero of Sustainable Production

Today, sustainability in manufacturing processes stands out not only as an environmental necessity but also as a strategy that provides a competitive advantage. In this context, printing services play a critical role in reducing the carbon footprint by making digital production processes more eco-friendly, flexible, and efficient. So, how can you enhance sustainability through the right use of printing services? Let’s explore the answer to this question in detail with the help of scientific data, industry experience, and innovative applications.

Is It Possible to Improve Resource Efficiency with 3D Printing Services?

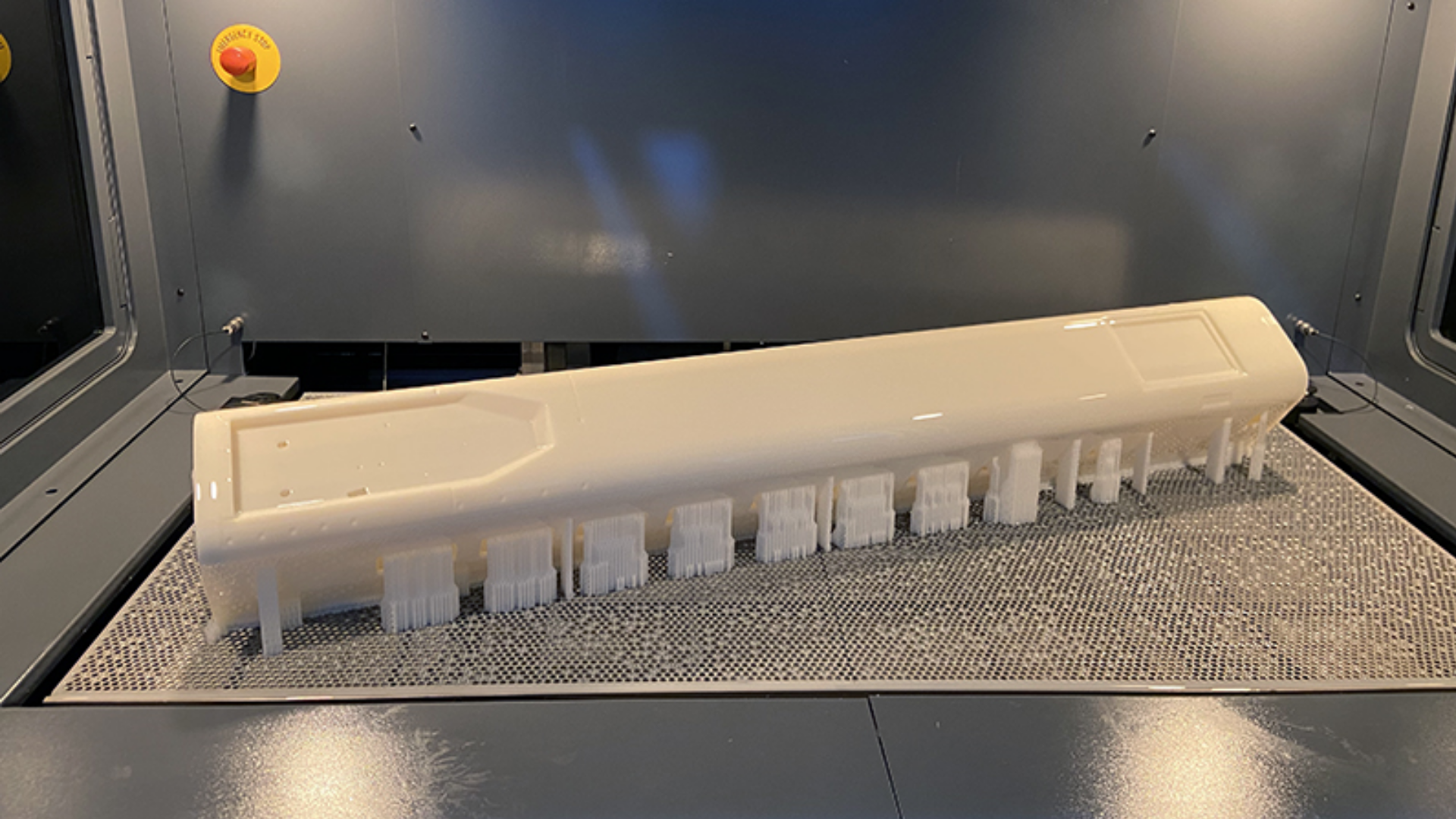

3D printing services (additive manufacturing) ensure that only the necessary amount of material is used during production, minimizing waste. With this method:

- The amount of raw material used in part production can be reduced by up to 70%,

- Carbon emissions in transportation processes can decrease by 40%,

- R&D costs can be reduced by 30% through integrated design and rapid prototyping.

These data show that 3D printing services not only reduce costs but also significantly strengthen sustainability in production processes. Brands like Prodigma offer these advantages practically through industrial 3D printing solutions.

What Should You Consider When Using 3D Printing Services?

If your goal is sustainable digital manufacturing, you should consider the following criteria when using 3D printing services:

- The filament or powder material used should be recyclable,

- The machinery should have high energy efficiency,

- Scrap rates should be kept to a minimum during production,

- Part designs should be optimized to save material,

- Product life cycle analysis should be conducted.

Following these criteria will help reduce the environmental impact of your production in a measurable way. Especially Prodigma’s 3D printing services support your environmental sustainability goals by offering recyclable material options and energy-efficient equipment.

Flexibility and Sustainability in Industrial Production with 3D Printer Services

3D printer services offer great convenience for responding quickly to sudden demands in industrial production. Compared to traditional manufacturing methods:

- Part production times can be reduced by up to 60%,

- Stockholding costs are eliminated,

- Unnecessary production is avoided,

- On-demand manufacturing reduces transport emissions.

These advantages not only make your production cycle more environmentally friendly through printing services but also allow you to build flexible production capacity. Especially in small-batch production demands, 3D printer services eliminate mold and tooling costs, contributing to a sustainable supply chain.

How Can You Use Printing Services to Meet Your Sustainability Goals?

To enhance sustainability in digital manufacturing through printing services, we recommend following these steps:

Design Optimization: Optimize your products to prevent unnecessary material use during production.

Use of Recyclable Materials: Prefer recyclable filaments such as PLA or PETG to reduce your carbon footprint.

Use of Energy-Efficient Equipment: Working with low-energy devices is both eco-friendly and cost-effective.

On-Site Production: Producing near the end-user helps reduce logistics-related emissions.

Prodigma-Supported Process Management: By contacting Prodigma, you can redesign your processes based on sustainability criteria and optimize your production and supply chain.

What Are Printing Services and How Do They Contribute to Sustainability?

Printing services are the general name for services that enable the production of digitally designed objects using 2D or 3D printers. Their contribution to sustainability includes:

- Eliminating the need for unnecessary stockpiling,

- Supporting a produce-as-needed approach,

- Minimizing material usage,

- Reducing waste generation,

- Enabling energy-efficient production.

What Are the Types of Printing?

Types of printing used in digital manufacturing include:

- FDM Printing: Filament is melted and shaped layer by layer.

- SLA Printing: Resin material is layered using laser curing.

- SLS Printing: Powder material is fused layer by layer with a laser.

- Metal 3D Printing: Production is achieved by sintering metal powders with laser energy.

Each type of printing provides different sustainability benefits. For example, SLA printing offers high precision, while FDM printing provides cost-effective and sustainable solutions.

Discover Printing Services for Sustainable Digital Manufacturing

Increasing sustainability in digital manufacturing through printing services is now accessible, economical, and efficient. By optimizing product life cycles, reducing waste rates, increasing energy efficiency, and minimizing your carbon footprint, you can benefit from 3D production processes. Working with a professional partner like Prodigma throughout this process will enhance your production quality and help you reach your eco-friendly manufacturing goals.

To take a step toward a more sustainable production journey, you can contact Prodigma and begin preparing your production processes for the future.