The Future Potential of 3D Printing in Advanced Material Manufacturing;

3D Printing Technology Revolutionizes the Defense and Aerospace Industries

Scientists at the Purdue Energetics Research Center are leveraging the unique capabilities of 3D printing technology to enhance the performance of high-energy materials. These materials include critical components like explosives, propellants, and pyrotechnic devices that can release significant amounts of energy. Innovative approaches in this field are finding broad applications, particularly in strategic industries such as defense and aerospace.

Customization Potential with 3D Printing

Diane Collard, who leads the project, focuses on tailoring high-energy materials to meet safety and performance requirements. The customization capabilities of 3D printing allow for the optimization of critical properties such as burn rates and energy release.

Collard is exploring innovative designs using reactive coatings and diverse geometric structures to modify the energy release properties of materials. Collaborations with the Air Force Research Laboratory (AFRL) are enabling breakthroughs that overcome the limitations of traditional manufacturing methods. Highlighting the significance of this technology, Collard states, "With 3D printing, we can develop bespoke solutions for every application."

Functional Gradient Materials and the Potential of Additive Manufacturing

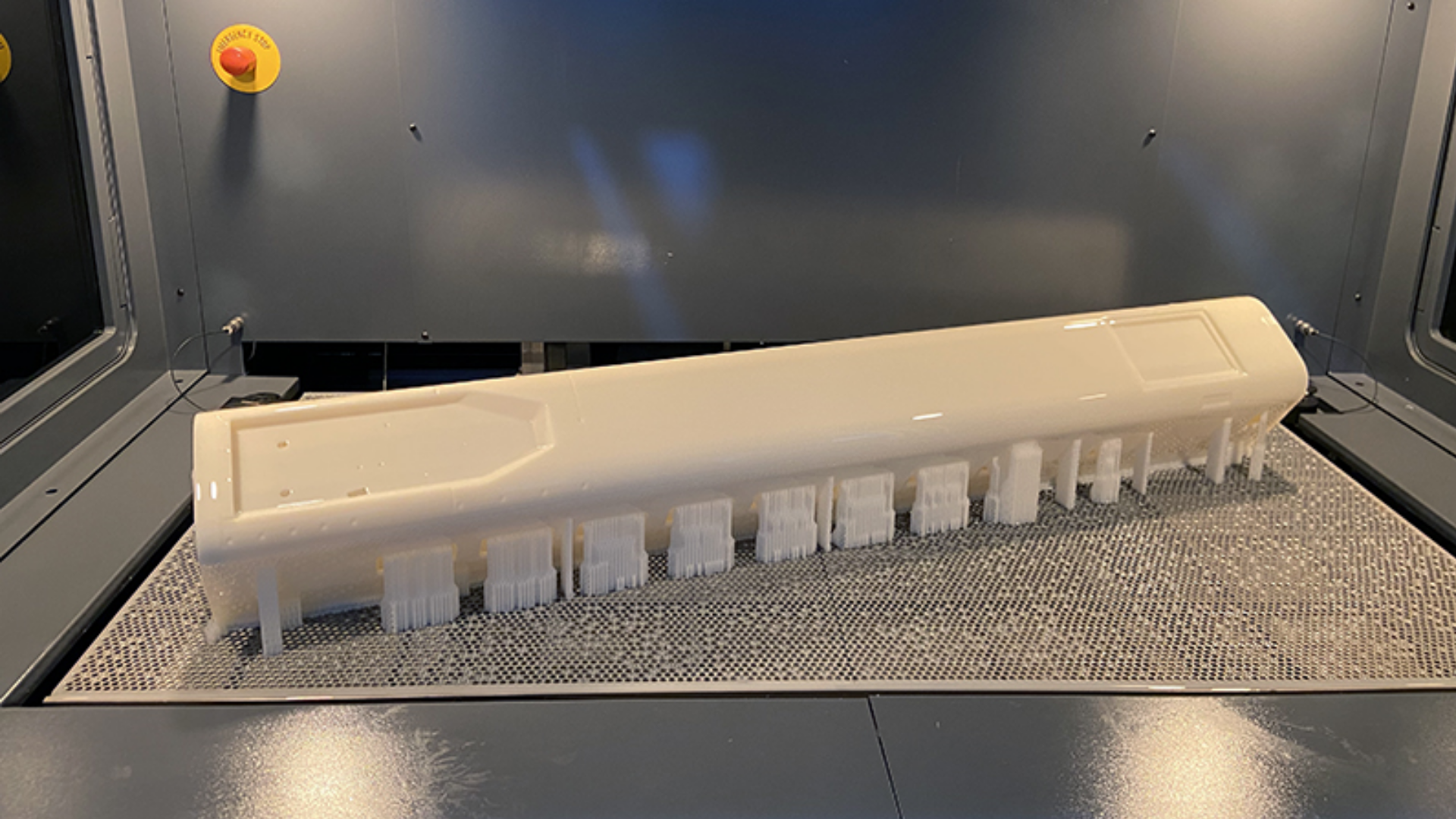

Researcher Kelsea Miller is working on innovative methods involving functional gradient materials, enabling high-energy components to possess varying properties. This approach showcases the transformative potential of 3D printing in large-scale design and production.

The flexibility provided by additive manufacturing processes allows materials to be designed specifically for each application. This adaptability not only transforms production methods but also expands the range of applications for these materials.

Conclusion: The Strategic Power of 3D Printing

These projects underscore the potential of 3D printing technology in developing high-energy materials. Enhancing material performance, improving safety standards, and delivering customized solutions are now achievable in critical industries such as defense and aerospace. Additive manufacturing is shaping the future of material science and its applications, paving the way for groundbreaking advancements.